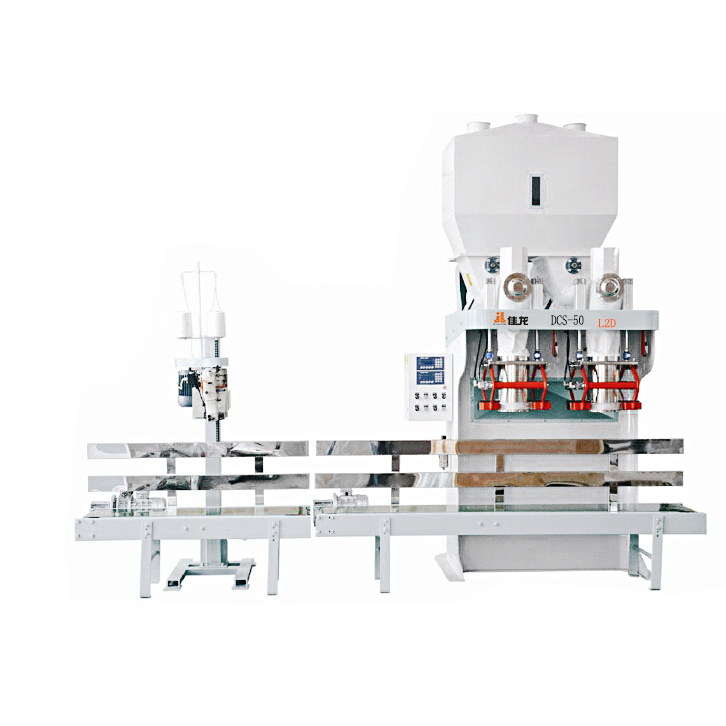

High-Speed Dual-Head Packaging Scale for Powders - Model DCS-25K-L3 (Double)

DCS-25K-L3 (Double) Rice Powder Flour Bag Filling Scale

The ultimate high-throughput solution for industrial-scale powder packaging. Featuring two independent weighing and filling stations, this machine is engineered to reach speeds up to 400 bags per hour.

It provides a complete, automated line for weighing, packaging, and conveying materials like rice powder and wheat flour, maximizing production efficiency.

Model: DCS-25K-L3 (Double)

Throughput: 350 - 400 bags/hour

Weighing Range: 10 - 25 kg

Product Highlights

Maximized Throughput

Two synchronized filling stations operate in tandem, dramatically increasing packaging speed for high-demand production.

Independent Precision Weighing

Each station has its own weighing system, ensuring that high speed does not compromise the ±0.2%FS accuracy.

Robust & Reliable Automation

Fully integrated system built with world-class components like NSK bearings for 24/7 reliability.

Centralized Intelligent Control

A single touch screen controls both stations with features like fault diagnosis and one-key recovery for simple operation.

Technical Specifications

| Model | DCS-25K-L3 (Double) |

| Weighing Range | 10 - 25 kg |

| Operation Speed | 350 - 400 bags/hour |

| Accuracy Grade | 0.2%F.S (Full Scale) |

| Air Requirement | 0.4 - 0.6 MPa |

Key Components Configuration

| Part Name | Brand / Origin | QTY |

|---|---|---|

| Loadcell | Keli (China) | 1 |

| Touch Screen | Xinjie (China) | 1 |

| Bearings | NSK (Japan) | 1 |

| Execute cylinder | Airtac (Taiwan) | 1 |

| Asynchronous motor | Wannan (China) | 2 |

| Level detector | IFM (Shanghai) | 1 |

Application Scenarios

1

Large-Scale Flour & Starch Mills

The ideal solution for high-volume bagging of wheat flour, rice powder, corn starch, and tapioca flour.

2

Food Ingredient & Seasoning Plants

Efficiently packages bulk sugar, salt, spices, milk powder, and protein supplements where high throughput is critical.

3

Fine Chemical & Mineral Production

Suitable for bagging non-corrosive fine chemical powders, pigments, and mineral powders like calcium carbonate.

4

Animal Feed & Premix Facilities

Perfectly handles the high-speed packaging of powdered feed additives and nutritional premixes.

Detailed Information

The Dual-Station Technical Advantage

The DCS-25K-L3's high speed is achieved through its intelligent, parallel processing design. While one station is discharging a precisely weighed bag, the other is simultaneously beginning the next weighing cycle. This tandem operation eliminates downtime between bags, leading to a continuous, fast-flowing production line managed by a single operator.

Our Manufacturing & Quality Assurance Process

Certified Component Sourcing: We procure components exclusively from globally recognized manufacturers. Each part is certified and inspected upon arrival.

Expert Assembly & Wiring: Our technicians are trained to assemble dual-head systems with exacting precision, ensuring perfect synchronization and adherence to safety standards.

48-Hour System Endurance Test: Every machine undergoes a 48-hour continuous run test, simulating a high-speed production environment to validate its stability, accuracy, and endurance.

Final Performance Audit: Before shipment, our QA team conducts a final audit, verifying all functions and safety interlocks to guarantee a flawless out-of-the-box experience.

Frequently Asked Questions (FAQ)

1. How much faster is this than a single-head machine?

The DCS-25K-L3 (Double) can reach speeds of 350-400 bags/hour, which is nearly double the output of our comparable single-head models.

2. Does a dual-head system require two operators?

No, the system is highly automated and designed to be efficiently managed by a single, trained operator through a centralized control panel.

3. What if one station needs maintenance?

The control system is integrated for synchronized operation. For routine maintenance, the entire machine is safely paused. The modular design with premium components minimizes the frequency of such stops.

4. Is the operation more complicated than a single-head machine?

No. The operator interacts with the system through a single, intuitive touch screen that manages both stations, making it just as user-friendly as a single-head machine.