High-Speed Semi-Automatic Rice Bagging Station - Model DCS-25K-3C

DCS-25K-3C High-Efficiency Rice Bagging & Filling Station

A complete semi-automatic solution for weighing and bagging granular materials like rice, wheat, beans, and seeds. The system combines high speed with user-friendly operation.

Featuring a dual-hopper design for speeds up to 900 bags/hour, Omron touch screen controls, and an integrated conveyor with a sewing machine, it is designed for maximum productivity.

Model: DCS-25K-3C

Capacity: 600-900 bags/hour

Material: Dual Stainless Steel Hoppers

Core Operational Advantages

High-Speed Dual-Hopper Design

Utilizes two 41L stainless steel hoppers that weigh in parallel, enabling continuous operation and exceptional speeds of up to 900 bags per hour.

Optimized Semi-Automatic Workflow

The operator simply places the bag. The machine then automatically weighs, fills, conveys the bag, and operates the sewing machine with automatic thread cutting.

Advanced & User-Friendly Controls

Features a premium Omron touch screen for easy operation and a high-precision controller with functions like auto error correction and fault diagnosis.

Precision Three-Stage Feeding

The three-level feeding system ensures every weighment is both fast and accurate, achieving an X(0.2) accuracy grade and minimizing material giveaway.

Technical Specifications

| Model | DCS-25K-3C |

| Weighing Range | 5 ~ 50 kg |

| Packing Speed | 600 ~ 900 bags/hour (varies with material and weight) |

| Accuracy Grade | X(0.2) |

| Sewing Machine Type | Single Needle / Double Thread |

| Power Supply / Consumption | 4N-AC 380V 50Hz / 1.1KW |

| Air Supply / Consumption | 0.4~0.6MPa / 2m³/h |

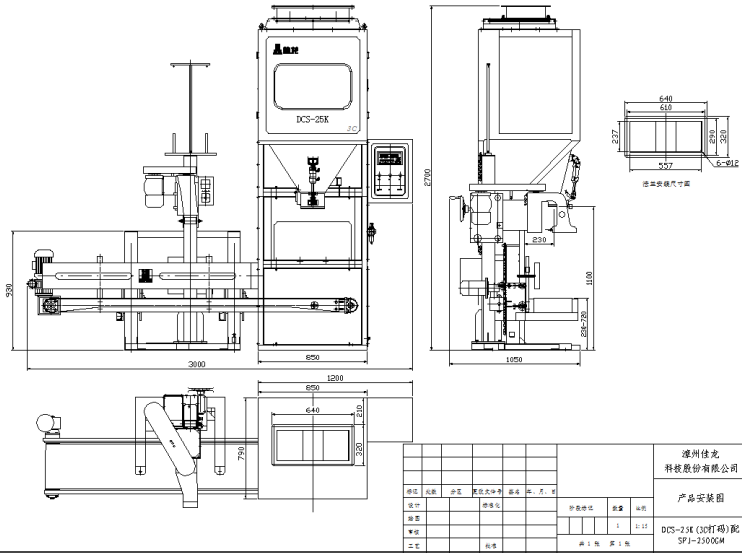

| Overall Dimensions (L×W×H mm) | 3000 × 1050 × 2700 |

In-Depth Product Information

Integrated System Design

The Semi Automatic 25kg Rice Bagging Filling Machine is delivered as a complete packing station, designed for quick integration and efficient operation. The full system includes the main packing scale body with its dual weighing hoppers, an industrial single-needle sewing machine, and a 2.5-meter conveyor with a hand wheel for easy height adjustment to accommodate different bag sizes.

Advanced Technical and Controller Advantages

Compact & Reliable Structure: A unique "one cylinder for four-stations" movement design results in a more compact machine structure, faster response times, and a significantly lower failure rate.

Intelligent System Functions: The controller provides an automatic alarm for over/under tolerance, features self-diagnosis for faults, and includes a one-key recovery function to easily press a reset key and return to default parameters.

Stable Performance: A super filter function provides powerful anti-vibration and anti-interference capabilities, ensuring the weighing process remains stable and accurate even in demanding factory environments.

Future-Ready Connectivity: Comes standard with a reserved RS232/485 interface for seamless data communication and integration with a central factory management system.

Built with High-Quality, Reliable Components

To guarantee long-term performance and reliability, this semi-automatic packing station is constructed using premium components from globally trusted suppliers.

| Component | Brand |

|---|---|

| Weighing Controller | CN/Zhiyuanda |

| Switching Power Supply | TW/Meanwell |

| Button, Knob | FR/Schneider |

| Load Cell | US/Celtron |

| Pneumatic Elements (Cylinder, Valve) | TW/Airtac |

Our Quality Guarantee and Customer Support

Quality Control: Every machine we produce undergoes a stringent quality control process. This includes raw material inspection, dimensional checks during fabrication, individual component testing, and a final, continuous operational test to ensure it meets our highest standards for speed and accuracy before leaving our facility.

Pre-Sales & After-Sales Service: Our expert team provides professional consultation to ensure you select the right equipment for your materials and production goals. We stand behind our machines with comprehensive after-sales support, including installation guidance, operational training, and long-term technical assistance with a full inventory of readily available spare parts to minimize any potential downtime.

Frequently Asked Questions (FAQ)

Q1: What does "semi-automatic" mean in terms of labor?

A1: It offers the perfect balance of automation and cost-effectiveness. The only manual step required is for an operator to place an empty bag onto the filling spout. The machine then handles everything else automatically: weighing the material, filling the bag, and conveying it through the sewing station where it is stitched closed with an automatic thread cutter.

Q2: How can this machine achieve a speed of up to 900 bags per hour?

A2: The high speed is made possible by the intelligent dual-hopper design. While one hopper is discharging its accurately weighed product into a bag, the second hopper is already being filled and weighed for the next cycle. This parallel processing eliminates waiting time and dramatically increases the machine's throughput compared to single-hopper systems.

Q3: How versatile is this machine for different products and bag sizes?

A3: The machine is highly versatile. Its wide weighing range of 5kg to 50kg makes it suitable for both large and small bags. Furthermore, the three-stage feeding system can be tuned to handle a wide variety of granular materials, from fine sugar to larger seeds and grains. The conveyor height is also easily adjustable via a hand wheel to accommodate bags of different lengths.