DCS-50S Semi-Automatic Granular Bagging System

Reliable & Cost-Effective Granular Packaging Solution

Our DCS-50-A3 pouch packing automatic machine is an integrated, semi-automatic bagging system designed for efficiency and precision. It's the perfect solution for businesses looking to upgrade their packaging line to accurately weigh and package a variety of granular materials like rice, wheat, beans, seeds, and sugar.

This complete system combines intelligent weighing with automated sewing and conveying, requiring only manual bag placement to achieve high-speed, consistent results.

Model: DCS-50-A3

Capacity: 300-400 bags/hour

Weighing Range: 5 - 50 kg

Exceptional Capabilities

High-Precision Weighing

Achieves X(0.2) accuracy grade with a three-level feeding system (fast, medium, trickle) and an advanced anti-vibration filter for stable, accurate measurements.

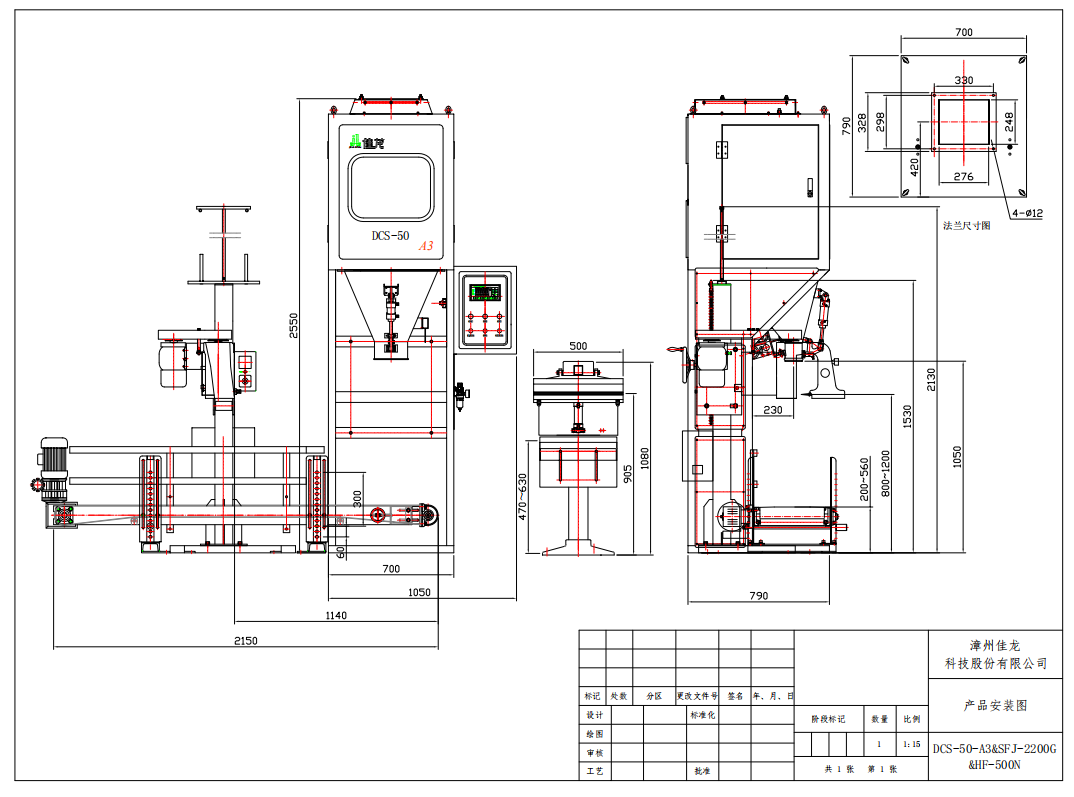

Complete Integrated System

This semi automatic bagger is a turnkey solution, including the packing scale body, a 2.2m screw-type lifting conveyor, and an automatic sewing machine with thread cutter.

Intelligent & User-Friendly Control

Features a smart controller with auto-error correction, alarms for weight tolerance, fault diagnosis, and a one-key function to easily restore default parameters.

Efficient & Compact Design

A single, powerful cylinder drives four-station movements (e.g., bag clamping/releasing), resulting in a compact structure, rapid response, and low failure rate.

Technical Specifications

| Weighing Range | 5 ~ 50 kg |

| Packing Speed | 300 - 400 bags/hour (dependent on material flow and operator speed) |

| Accuracy Grade | Class X(0.2) |

| Scale Display Interval | 10 g |

| Sewing Machine Type | Single Needle / Double Thread, with auto thread cutter |

| Power Requirements | AC 380V, 3-Phase 4-Wire, 50Hz / 1KW |

| Air Supply / Consumption | 0.4 - 0.6 MPa / 1 m³/h |

| Materials | Material Contact Parts: 304 Stainless Steel (78L hopper); Frame: Painted Carbon Steel |

| Required Installation Height | 2550 mm |

| Data Interface | Reserved RS232/485 Port |

Versatile Application Scenarios

1

Grain Milling & Processing

Ideal for rice bag packing machine operations, wheat, corn, and various bean packaging for distribution.

2

Agricultural Seed Industry

Provides accurate, gentle packaging for various crop seeds, protecting viability and ensuring proper weight.

3

Food Ingredient Production

Efficiently handles bulk food ingredients such as sugar, salt, and other crystalline or granular materials.

4

Small to Medium Enterprises

An excellent investment for growing businesses needing to increase throughput beyond manual scooping.

Our Commitment to Quality and Service

Built with Reliable Components

We construct our bagging systems using components from trusted international and domestic brands to ensure stable performance and a long service life. This includes key electrical parts from Schneider, reliable pneumatic elements from Airtac and Meanwell, and robust motors and load cells.

Manufacturing & Quality Assurance

Each automatic bagging machine is assembled by skilled technicians following strict engineering standards. Before dispatch, every unit undergoes comprehensive testing, including a continuous operational run, to verify that all mechanical and electrical systems function flawlessly, guaranteeing you receive a machine that is ready for production.

Dedicated Customer Support

Pre-Sales Consultation: Our expert team will help you select the right configuration for your specific materials and operational needs.

After-Sales Service: We provide detailed manuals, video support for installation and operation, a 1-year warranty on core components, and lifetime access to technical assistance and spare parts.

Frequently Asked Questions (FAQ)

Q: What does "semi-automatic" mean for this machine?

A: It means the machine automatically performs the weighing, filling, and bag sewing/sealing. The operator's main task is to manually place an empty pouch or bag onto the filling spout.

Q: What kind of bags can be used with this system?

A: This bagging system is designed for pre-made, open-mouth bags such as PP woven bags, kraft paper bags, and poly-lined paper bags.

Q: Is it difficult to operate and maintain?

A: The machine is designed for ease of use. The intelligent controller is straightforward, and routine maintenance is simple, mainly consisting of cleaning and periodic checks of the sewing machine and pneumatic components. We provide full documentation to guide you.