Automatic Vertical Form-Fill-Seal (VFFS) Machine for Liquids, Pastes, and Sauces

Automatic VFFS Machine for Liquids & Pastes

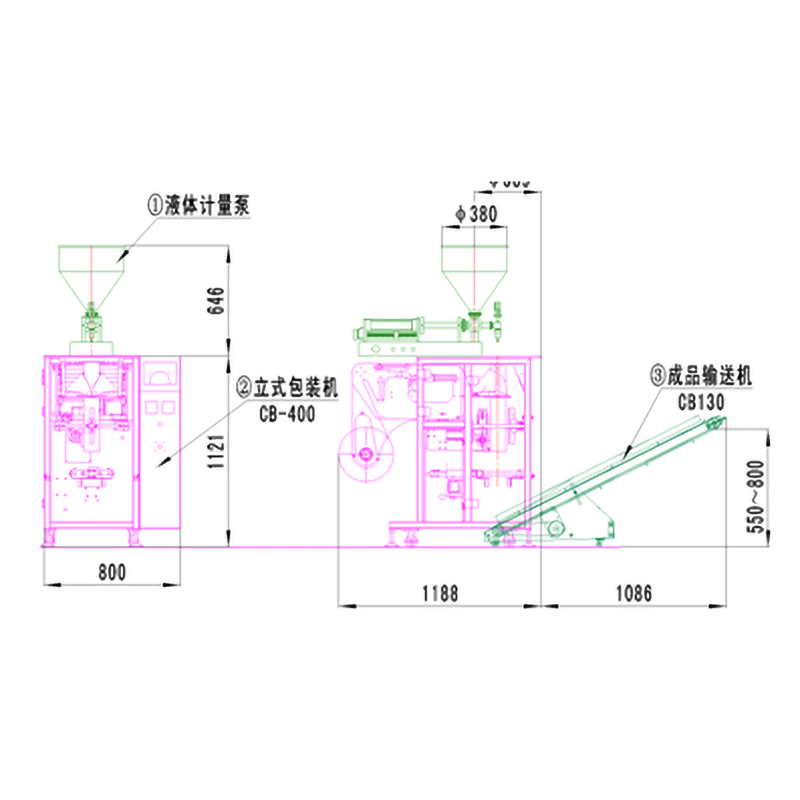

An advanced packaging solution for liquids, pastes, and sauces, refined over 10 years for high automation and reliability. This system integrates seamlessly for an efficient workflow that saves on labor costs.

Capacity: Max 30 bags/min

Labor Requirement: 1 Worker

Key Feature: Optional Paste Pump Integration

Product Highlights

High Automation & Labor Savings

This fully automatic system is designed for easy operation and can be controlled by a single worker, saving on labor costs.

Intelligent Linkage Control

Features automatic feeding that is linked to the machine's operation; it intelligently stops when there are no materials to save waste.

Proven Reliability & Durability

Refined over a decade of continuous improvement, this packaging solution has been optimized for a low failure rate.

Versatile Liquid & Paste Handling

The machine can be perfectly matched with an optional paste pump, making it ideal for packaging thick materials.

Technical Specifications

| Parameter | Value |

| Capacity | Approx. 30 bags/min (Depending on material & film quality) |

| Accuracy | ≤±1% |

| Maximum Film Width | 320 mm |

| Bag Type | Pillow bag, Punching bag (with hole) |

| Film Pulling Type | Single-belt pulling film |

| Maximum Filling Range | 500 ml |

| Film Thickness | 0.04 - 0.09 mm |

| Compatible Film Materials | Heat-sealable laminates (BOPP/VMCPP, PET/PE, BOPP/CPP, PET/AL/PE etc) |

| Air Consumption | 0.8Mpa, 0.5m³/min |

| Total Power | 2.945 KW |

| Voltage | 380V / 50HZ (Three-phase four-wire) |

| Required Air Compressor | Not less than 1 CBM |

| Total Height of Equipment Set | 1.767 m |

Application Scenarios

1

Food & Condiments

Ideal for ketchup, mayonnaise, chili sauce, salad dressing, honey, jam, and cooking oil.

2

Cosmetic & Personal Care

Perfect for packaging shampoo, conditioner, lotions, liquid soap, and cosmetic creams.

3

Household & Industrial

Suitable for non-corrosive liquid detergents, cleaning agents, adhesives, and gels.

4

Pharmaceutical & Health

Excellent for syrups, herbal pastes, and liquid health supplements.

Frequently Asked Questions (FAQ)

Q1: What is "linkage control" and why is it important?

A1: Linkage control means that the material feeding system (e.g., a paste pump) and the packaging machine are electronically connected and synchronized. The machine intelligently controls the pump, telling it when to feed product. This ensures a seamless, efficient operation and prevents material waste if the packaging process stops.

Q2: What kinds of bags can this machine produce?

A2: The primary bag style is a standard "pillow bag," which is very common for liquids and snacks. Additionally, the machine can be equipped with an optional punching device to create a hanging hole in the bag's seal, which is useful for retail display purposes.

Q3: Is the machine difficult to maintain?

A3: The machine is designed with over a decade of improvements aimed at ensuring a low failure rate and easy operation. Its high degree of automation and user-friendly controls mean that maintenance is straightforward, and a single trained worker can manage its daily operation.

Q4: What ancillary equipment do I need to run this machine?

A4: To operate this VFFS packaging line, you will need a 380V three-phase electrical supply and a dedicated air compressor with a capacity of not less than 1 cubic meter per minute to power the pneumatic components. If you are packing a paste, you will also need a compatible paste pump.