PZB-700-F5S Granule Weighing Vacuum Packaging Machine

PZB-700-F5S Granule Weighing Vacuum Packaging Machine

Optimized for granular flow materials, suitable for automated weighing and vacuum packaging of various granular products such as rice, mixed grains, beans, seeds, seasonings, etc.

Equipped with Japan Omron PLC core control and high-definition touch screen, automatic parameter setting, real-time monitoring of production process, intuitive and easy operation.

Model: PZB-700-F5S

Capacity: 550-700 bags/hour

Material: Industrial-grade stainless steel

Core Features

Dual-station Efficient Production

Independent dual working unit design, capable of handling packaging tasks of two different specifications or materials simultaneously.

Precision Weighing Control

Achieves ultra-high precision weighing ≤0.5% (1-10kg range).

Long-lasting Vacuum Preservation

German original vacuum pump provides stable and powerful vacuum performance.

Industrial-grade Reliability

All key components use internationally renowned brands to ensure long-term stable operation.

Technical Specifications

| Model | PZB-700-F5S |

| Weighing Range | 1~10kg |

| Working Efficiency | 550~700 bags/hour |

| Weighing Accuracy | Class X(0.5) (Error ≤ ±0.5%) |

| Power Parameters | 4N-AC380v 50Hz 3.3kw |

| Air Source Requirement | 0.4~0.6MPa · 25m³/h |

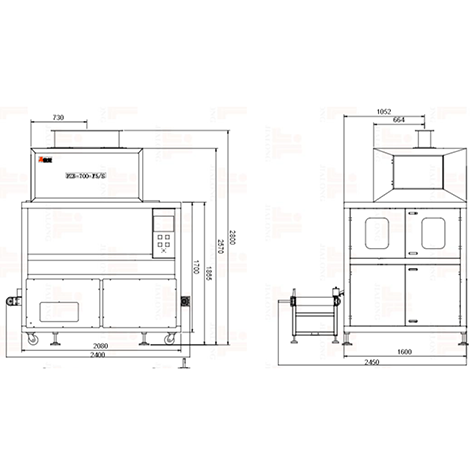

| Dimensions | 1850×2050×2500mm (L×W×H) |

Application Scenarios

1

Grain Processing

Precision vacuum packaging of grains such as rice, soybeans, mixed grains, etc.

2

Seed Technology

Precise measurement and vacuum sealed packaging of crop seeds

3

Food Processing

Fresh-keeping packaging of foods such as coffee beans, sugars, nuts, pet dry food, etc.

4

Seasoning Industry

Moisture-proof and fresh-keeping packaging of seasonings such as pepper, chili, etc.

Product Description

Granule Weighing and Vacuum Packaging System

Optimized for granular flow materials, suitable for automated weighing and vacuum packaging of various granular products such as rice, mixed grains, beans, seeds, seasonings, etc.

Technical Features

Adaptive Control Technology: System has self-learning capability for material characteristics

Triple Stability Guarantee Mechanism: Sturdy structural design ensures equipment reliability

Intelligent Heat Sealing System: Achieves precise temperature control

Modular Engineering Structure: Key components can be quickly disassembled and cleaned

Multiple Safety Protections: Integrated material jamming detection, vacuum anomaly alarm

Industry 4.0 Ready: Pre-installed communication interfaces support system integration

Quality Control

Strict Supplier Selection: All core components come from globally renowned brand suppliers

Precision Assembly Process: Completed by experienced engineering teams

Multi-stage Functional Testing: 72-hour continuous simulation testing

Comprehensive Factory Inspection: Each unit undergoes final verification before shipment

Service Support

Professional Consultation: Free technical consultation and customized solutions

Worry-free Delivery: Detailed installation drawings and technical guidance

Operation Training: Comprehensive training on operation, maintenance and safety procedures

After-sales Service: Nationwide service network support, regular follow-ups

Frequently Asked Questions

Q: What types of materials is the equipment suitable for? A: Ideal for free-flowing granular materials (grains, beans, seeds, etc.)

Q: What packaging accuracy can be achieved? A: Class X(0.5) accuracy within 1-10kg range (error ≤ ±0.5%)

Q: What is the maximum production capacity? A: Up to 700 bags/hour