LZB-700-R7 Automatic Packaging Machine

LZB-700-R7 Automatic Packaging Machine

The LZB-700-R7 is a state-of-the-art automatic packaging machine designed to deliver precision, speed, and durability. Perfect for handling granular and powder materials, this machine is a reliable solution for businesses seeking to optimize their packaging processes.

Its advanced technology ensures seamless operation, making it an essential asset for modern production environments.

Model: LZB-700-R7

Capacity: 660–720 bags/hour

Material: High-quality stainless steel and carbon steel

Core Features

High-Speed Weighing

Features an advanced control system with automatic parameter correction for consistent results across diverse materials.

Intuitive Interface

Includes a 10-inch Omron touch screen and PLC for easy operation and real-time monitoring.

Top-Tier Components

Incorporates SMC pneumatic parts from Japan and a Leybold vacuum pump from Germany for exceptional reliability.

Space-Saving Design

Compact footprint optimizes factory floor space.

Technical Specifications

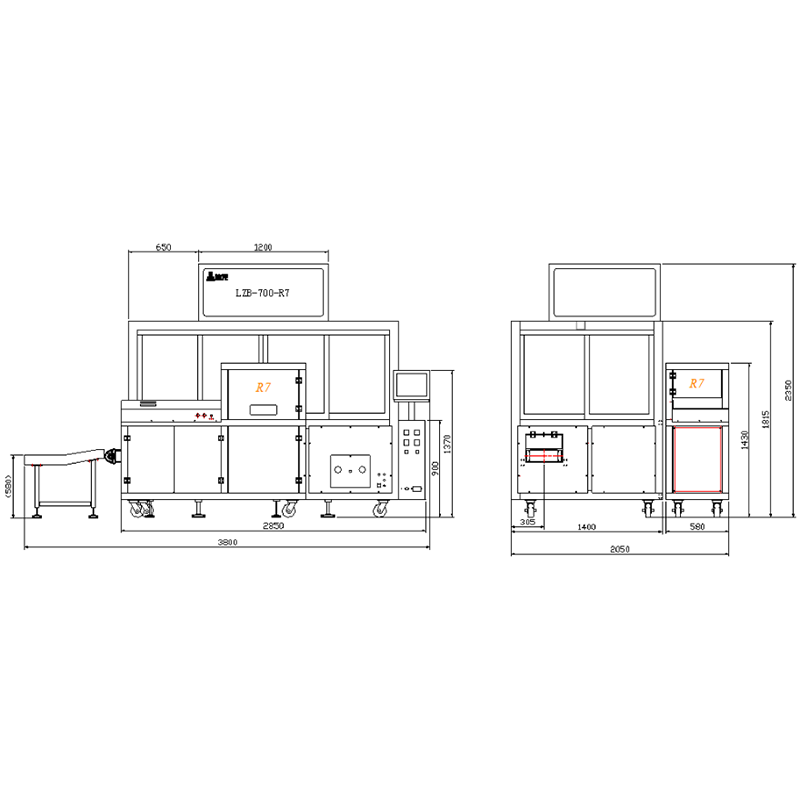

| Model | LZB-700-R7 |

| Appearance | Sleek, industrial-grade design with a robust finish |

| Dimensions | 3800 mm (L) × 2050 mm (W) × 2350 mm (H) |

| Materials | High-quality stainless steel and carbon steel for durability |

| Packing Range | 0.5–2.5 kg |

| Packaging Speed | 660–720 bags/hour (tested with rice) |

| Accuracy | X(0.5), ensuring precise measurements |

| Power Supply | 4N-AC 380V, 50Hz, 5.2 kW |

| Air Consumption | 0.4–0.6 MPa, 24 m³/h |

| Certifications | CE, ISO 9001:2015 |

Application Scenarios

1

Food Processing

Ideal for packaging grains, spices, or powdered ingredients

2

Agriculture

Perfect for seeds, fertilizers, and other farm products

3

Chemical Manufacturing

Handles granular chemicals with precision and safety

4

Pharmaceuticals

Suitable for packaging powdered or granular medical goods

Product Description

LZB-700-R7 Automatic Packaging Machine

The LZB-700-R7 is a state-of-the-art automatic packaging machine designed to deliver precision, speed, and durability. Perfect for handling granular and powder materials, this machine is a reliable solution for businesses seeking to optimize their packaging processes. Its advanced technology ensures seamless operation, making it an essential asset for modern production environments.

Product Features

Equipped with high-speed weighing technology, an intuitive 10-inch Omron touch screen, and top-tier components like SMC pneumatic parts and a Leybold vacuum pump, the LZB-700-R7 offers versatile performance for a wide range of packaging needs.

Its compact design and precise Celtron load cells ensure efficiency and accuracy in every cycle.

Product Advantages

Boosted Productivity: Capable of processing up to 720 bags per hour, enhancing workflow efficiency

Long-Lasting Build: Constructed with premium materials to endure rigorous use

Energy Efficiency: Operates on just 5.2 kW, minimizing power costs

Simplified Maintenance: Modular design and self-diagnostic features reduce downtime

Flexible Options: Adjustable settings cater to specific material and bag requirements

Technical Advantages

The LZB-700-R7 boasts smart operation with an Omron PLC and touch screen, dependable mechanics with SMC cylinders and solenoid valves, superior sealing via a German Leybold vacuum pump, and accurate weighing with Celtron load cells and ABBA linear slides.

Company Strengths

Proven Expertise: Over 15 years of leadership in packaging machinery innovation. Worldwide Presence: Trusted by customers in more than 30 countries across various industries. Commitment to Quality: Certified under ISO 9001:2015 for consistent excellence. Innovation Focus: Ongoing R&D ensures cutting-edge solutions tailored to market needs.

Quality Control

Our production process guarantees reliability with premium materials sourced from certified suppliers, skilled assembly by expert technicians, thorough testing for performance and durability, and detailed final inspections to meet stringent standards.

Corporate Social Responsibility

Sustainability is at our core with an energy-saving design that reduces environmental impact, responsible sourcing from ethical suppliers, and community support through initiatives like aiding local agriculture and education programs.

Pre-Sales and After-Sales Service

Pre-Sales Support: Free consultations to understand your needs and tailored demonstrations (virtual or in-person). After-Sales Commitment: 24/7 technical assistance, comprehensive manuals and video tutorials, a one-year warranty with extension options, and on-site training and maintenance (availability varies by region).

Customer FAQs

What materials can it package? Granular and powder items like grains, seeds, and chemicals.

Is it user-friendly? Yes, the Omron touch screen simplifies operation, and training is included.

What’s the warranty period? One year standard, with extension options available.

Can it be tailored to my needs? Absolutely, settings adjust for different materials and bag sizes.

How is maintenance managed? Self-test functions and a modular build make it easy to maintain.

Main Configurations

| Item | Name | Supplier |

| 1 | Touchscreen 10" | Japan / OMRON |

| 2 | Controller | Shenzhen / General |

| 3 | PLC | Japan / OMRON |

| 4 | Switching Power Supply | Japan / OMRON |

| 5 | Solid State Relay | Japan / OMRON |

| 6 | Intermediate Relay | Japan / OMRON |

| 7 | Loadcell | USA / Celtron |

| 8 | Phase Sequence Protective Relay | France / Schneider |

| 9 | Vacuum Pump | Germany / LEYBOLD |

| 10 | Cylinder | Japan / SMC |

| 11 | Electromagnetic Valve | Japan / SMC |

| 12 | Linear Slide | Taiwan / ABBA |

| 13 | Micro Reduction Motor | Taiwan / CHENTA |