Z-Series Vertical Conveyor for Gentle Material Handling

Jialong Z-Series Vertical Conveyor Systems

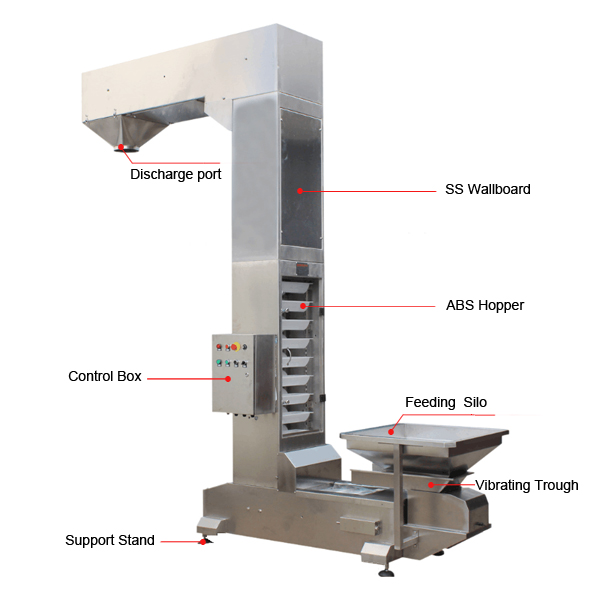

Elevate your production with Jialong's Z-Series Vertical Conveyor, the definitive solution for gentle, efficient, and space-saving material handling. This advanced Z-type bucket elevator is expertly designed to transport a wide range of granular and delicate materials with minimal product degradation.

With its fully enclosed, sanitary design and intelligent automation, the Z-Series seamlessly integrates into food, agriculture, and chemical processing lines, ensuring product integrity and maximizing operational efficiency.

System: Z-Type Bucket Elevator

Capacity: Up to 35 m³/hour

Core Feature: Gentle & Hygienic Vertical Conveying

Key Advantages

Gentle Product Handling

Vibration-assisted feeding and smooth bucket transitions minimize impact and friction, significantly reducing damage to fragile materials like seeds, nuts, and puffed foods.

Hygienic & Enclosed Design

Constructed from 304 stainless steel with a fully enclosed housing, this Z lift prevents dust leakage and external contamination, meeting stringent food safety standards.

Space-Saving Footprint

The Z-shape elevator configuration optimizes vertical space, offering a compact footprint that is ideal for facilities with limited floor area, saving valuable production space.

Intelligent & Automated

Equipped with smart sensors to monitor material levels, the system automatically starts and stops, ensuring continuous flow to downstream equipment while optimizing energy use.

Technical Specifications

| Parameter | Z-2L | Z-4L | Z-6L | Z-8L |

|---|---|---|---|---|

| Capacity (m³/h) | ≤6 | ≤15 | ≤25 | ≤35 |

| Motor Power (KW) | 1.1 | 1.5 | 2.2 | 3.0 |

| Bucket Capacity (Liters) | 2 | 4 | 6 | 8 |

| Casing Wall Thickness (mm) | 2.5 | |||

| Control Unit Dimensions (W×D) | 450 × 530 mm | 490 × 610 mm | 490 × 746 mm | 490 × 973 mm |

Application Scenarios

1

Food Manufacturing

Ideal for the vertical conveying of delicate food products, including snack foods, nuts, frozen goods, and confectioneries, while meeting food safety standards.

2

Agricultural Processing

The Z-shape elevator provides gentle handling solutions for seeds, grains, and legumes, preserving quality from intake to packaging.

3

Chemical & Plastics Industry

Reliably transport plastic pellets, masterbatch, and other non-corrosive chemical compounds within a sealed, contamination-free system.

4

Integrated Production Lines

Seamlessly connect with weighing machines, packaging systems, and color sorters to create a fully automated, multi-level production workflow.

In-Depth Details

Quality & Engineering Excellence

Jialong Technology's Z-Series conveyors are the benchmark for quality in vertical material handling. Each Z lift is constructed with a robust frame and premium 304 stainless steel for all product-contact areas, ensuring durability and compliance with strict hygiene standards. The precision-engineered chain and bucket assembly guarantees smooth, reliable performance and minimizes material degradation. Our commitment to sustainable engineering is reflected in the automated, energy-efficient operation that reduces power consumption and optimizes material usage. Every unit undergoes rigorous factory testing to ensure it meets our high standards for performance, safety, and reliability.

Comprehensive Customer & Technical Support

Custom Engineering & Consultation: Our technical team collaborates with you to design a custom Z-type bucket elevator solution, analyzing your plant layout, material flow, and throughput needs to create the most efficient system.

Installation and Commissioning: We provide full technical documentation, including detailed CAD drawings and installation manuals. Our engineers are also available for remote or on-site support to ensure a seamless setup.

Dedicated Service & Spare Parts: We stand behind our equipment with dedicated service and maintain a comprehensive inventory of all critical spare parts, including buckets, chains, motors, and sensors, for rapid dispatch.

Frequently Asked Questions (FAQ)

Q1: What is the main advantage of a Z-type bucket elevator compared to a standard vertical bucket elevator?

A: A standard vertical elevator typically scoops material at the bottom and centrifugally discharges it at the top, which can damage fragile products. The Z-type elevator gently picks up material on a horizontal plane, lifts it vertically, and then gently discharges it on another horizontal plane, which dramatically reduces product breakage and makes it ideal for delicate materials.

Q2: Can the conveyor's height and length be customized?

A: Absolutely. The Z-Series is fully modular. The horizontal and vertical sections of the Z shape elevator can be customized in length and height to perfectly match the specific layout and elevation requirements of your production line, connecting machines at different levels seamlessly.

Q3: Is the system difficult to clean and maintain?

A: No, it is designed for simplified service. The fully enclosed housing prevents most external contamination. For cleaning, easy-access panels and the design of the buckets allow for straightforward washing and sanitation to prevent cross-contamination between different products. Routine maintenance is minimal.