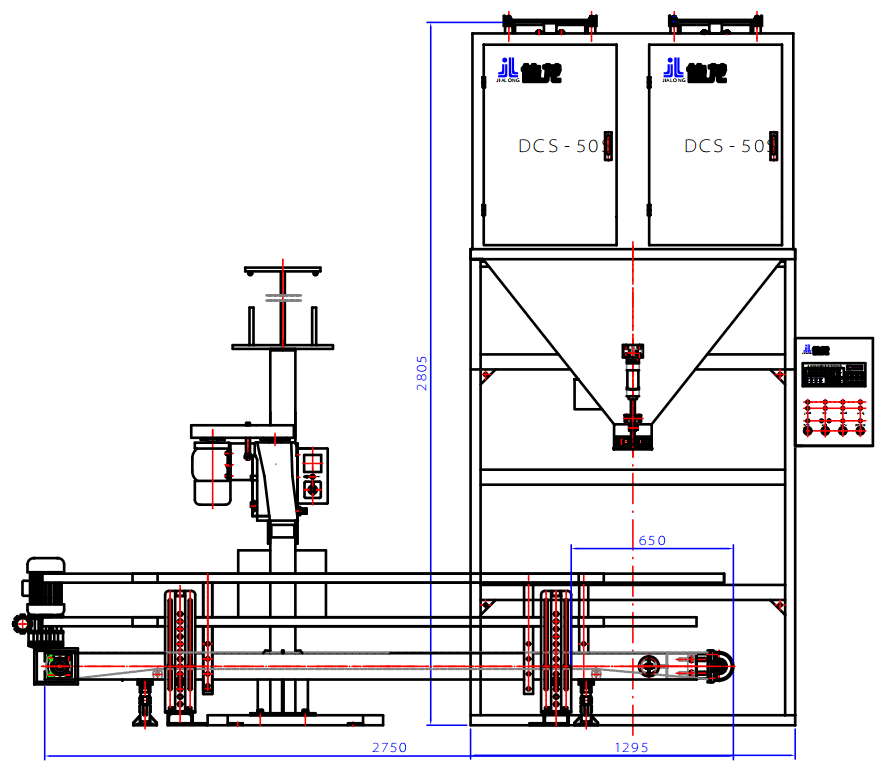

DCS-50S Semi-Automatic Granular Packaging Machine

DCS-50S High-Speed Semi-Automatic Weighing & Bagging Machine

Achieve superior efficiency in your packaging operations with the DCS-50S, a high-performance semi-automatic machine designed for a wide range of granular and powder materials. From agricultural products like millet and wheat to industrial powders and food ingredients, this system delivers speed, accuracy, and reliability.

Featuring an innovative dual-feed weighing system and built with premium international components, the DCS-50S is engineered to maximize throughput and ensure consistent quality in every bag.

Model: DCS-50S

Capacity: 500 - 600 bags/hour

Core Technology: Dual-Feed Precision Weighing

Key Advantages

Dual-Feed High-Speed Design

This wheat packing machine uses a simultaneous feeding and weighing system, which dramatically increases packing speed and boosts production yield compared to single-feed models.

Intelligent & Precise Weighing

Equipped with a high-precision controller that provides automatic error correction, ensuring every bag is weighed to an accuracy of Class X(0.2) for minimal product give-away.

Robust & Reliable Components

Built with globally recognized components from Schneider and Airtac, and a hygienic stainless steel material path, this machine guarantees long-term stability and performance.

Smart System Diagnostics

The advanced control system includes comprehensive diagnostics with alarms for over/under tolerance and fault detection, ensuring operational safety and quality control.

Technical Specifications

| Parameter | Model: DCS-50S |

| Weighing Extent | 20 - 50 kg |

| Operation Speed | 500 - 600 bags/hour |

| Accuracy Grade | Class X(0.2) |

| Scale Interval (Resolution) | 10 g |

| Power Requirement | 4N-AC 380V / 50Hz, 1 KW |

| Air Requirement | 0.4~0.6 MPa, 1 m³/hour |

| Installation Height | 3100 mm |

Main Component Configuration

| Component | Brand / Supplier |

| Weighing Controller | Zhiyuanda |

| Power Switch | Taiwan/Meanwell |

| Button | France/Schneider |

| Load Cell | ZEMIC |

| Pneumatic Elements (Cylinder, Solenoid Valve) | Taiwan/Airtac |

Diverse Application Scenarios

1

Agricultural Grain Packaging

The perfect millet packaging machine, this unit also excels at packaging other grains like rice and wheat, along with various seeds and legumes, making it a cornerstone for agricultural suppliers.

2

Food Ingredient Industry

Ideal for food processing facilities, this machine accurately weighs and bags bulk food ingredients such as sugar crystals, salt, and various food-grade powders with speed and precision.

3

Powdered Goods Production

From flour and spices to protein powders, this versatile system provides a reliable solution for producers needing a high-efficiency wheat bag packing machine or powder filler.

4

Industrial Chemical Packaging

Well-suited for chemical manufacturing operations, this equipment reliably packages a wide range of industrial powders, such as chemical compounds and detergents, in a safe and efficient manner.

In-Depth Details

Operational Workflow

The DCS-50S offers a streamlined, user-friendly workflow. An operator manually places an empty bag onto the filling spout and initiates the cycle. The machine then automatically clamps the bag in place. The high-speed dual-feed system accurately weighs the material and dispenses it into the bag. Once the precise weight is reached, the bag is automatically released onto a conveyor (optional) for transfer to a sealing or sewing station. This semi-automatic process provides an optimal balance of speed and manual control.

Our Commitment to Quality & Sustainable Manufacturing

Jialong Technology is dedicated to building robust and reliable machinery. This millet packaging machine is manufactured using a heavy-duty framework and high-grade stainless steel for all material-contact parts to ensure durability and food safety compliance. We partner with world-class component suppliers to guarantee performance and longevity. By designing energy-efficient equipment that improves accuracy and reduces product waste, we contribute to more sustainable production practices for our clients worldwide.

Comprehensive Service & Technical Support

Expert Application Consultation: Our technical team is available to analyze your specific material (e.g., wheat, rice, powders) and production goals to confirm the DCS-50S is perfectly configured for your needs.

Full-Service Technical Assistance: We offer complete support, including detailed user manuals and remote engineering assistance, to guide you through installation, setup, and operator training.

Guaranteed Spare Parts Availability: We maintain a full inventory of all essential spare parts to ensure rapid delivery and minimize any potential operational downtime.

Frequently Asked Questions (FAQ)

Q1: What is the main advantage of the dual-feed system?

A: The dual-feed weighing system allows one batch of material to be weighed while the previous one is being discharged. This parallel process eliminates the time a machine would normally pause for weighing, nearly doubling the potential packing speed compared to a traditional single-feed design.

Q2: Is this machine suitable for very fine or dusty powders?

A: Yes, the DCS-50S is versatile enough to handle many free-flowing powders. However, for extremely fine, non-free-flowing, or aerated powders, we recommend consulting with our team, as a specialized auger filler or a system with enhanced dust collection may be more suitable.

Q3: How easy is it to integrate this wheat bag packing machine into an existing line?

A: Integration is straightforward. The machine has a compact footprint and is equipped with a reserved RS232/485 communication interface. This allows it to easily connect with upstream equipment (like elevators) and downstream machinery (like conveyors and palletizers) for a cohesive production line.